3-D Printing: Fad or Here to Stay?

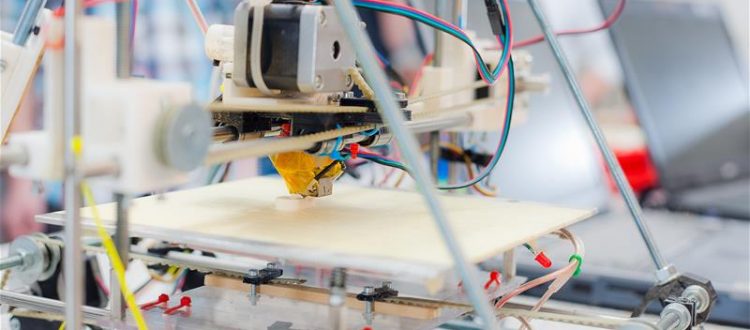

3-D printing is the process of “printing” three dimensional objects designed on a computer. Most printers use plastic strands that are heated through the printer then formed across X and Y axis’s according the design file. All kinds of items are being 3-D printed, from the controversial (guns), to the weird (model fetuses), to the useful (replacement table legs). 3-D printing has opened up a whole new world for startups and small businesses. In an article on VentureBeat.com, an MIT startup has launched a customizable 3-D printed jewelry store for Valentine’s Day gifts. The company, Matter.io has launched the service on the site Dyo.co (short for “design your own”) where anyone with an Internet connection can use templates and tools to design their own jewelry. 3-D printing has really innovated manufacturing because things can now be created at a scale of one-to-one. Small businesses and startups can now prototype from their basements or living rooms. They can create, scrap and create again without ever leaving their houses. Manufacturing orders no longer have to be placed in bulk and shipped from overseas. They can be “just in time” manufactured as the art, jewelry, part, etc. is ordered. As far as whether it sticks around or fades away? I think that question will be answered by the market. Is this something that people en-masse want to use? Is it a niche that small startups and business can use to manufacture very specific parts? Currently, most 3-D printers are fairly expensive and quite large. The industry as a whole is working to make the printers smaller and more affordable so that more people can start using them. I think the 3-D printing process is here to stay, just in what capacity is yet to be determined. If you have interest in the 3-D printing process, do some research online. You’ll find plenty of information on the current products on the market and how the whole process works. Maybe you’ll come across a way to use 3-D printing in your business.

3-D printing is the process of “printing” three dimensional objects designed on a computer. Most printers use plastic strands that are heated through the printer then formed across X and Y axis’s according the design file. All kinds of items are being 3-D printed, from the controversial (guns), to the weird (model fetuses), to the useful (replacement table legs). 3-D printing has opened up a whole new world for startups and small businesses. In an article on VentureBeat.com, an MIT startup has launched a customizable 3-D printed jewelry store for Valentine’s Day gifts. The company, Matter.io has launched the service on the site Dyo.co (short for “design your own”) where anyone with an Internet connection can use templates and tools to design their own jewelry. 3-D printing has really innovated manufacturing because things can now be created at a scale of one-to-one. Small businesses and startups can now prototype from their basements or living rooms. They can create, scrap and create again without ever leaving their houses. Manufacturing orders no longer have to be placed in bulk and shipped from overseas. They can be “just in time” manufactured as the art, jewelry, part, etc. is ordered. As far as whether it sticks around or fades away? I think that question will be answered by the market. Is this something that people en-masse want to use? Is it a niche that small startups and business can use to manufacture very specific parts? Currently, most 3-D printers are fairly expensive and quite large. The industry as a whole is working to make the printers smaller and more affordable so that more people can start using them. I think the 3-D printing process is here to stay, just in what capacity is yet to be determined. If you have interest in the 3-D printing process, do some research online. You’ll find plenty of information on the current products on the market and how the whole process works. Maybe you’ll come across a way to use 3-D printing in your business.